Your shipping cases for trade shows are the unsung heroes of your event marketing strategy. They are your first and best defense against the logistical chaos of transport, turning a potential disaster into a smooth, professional setup. Investing in the right cases from the start is an insurance policy for your most valuable marketing assets, ensuring your booth arrives looking sharp, every single time.

This isn't just about avoiding damage; it's a direct investment in your brand’s reputation and your event's success. But with so many options, how do you choose the right cases and develop a system that saves you time, money, and stress?

Why High-Quality Cases Define Your Trade Show Success

Every marketing manager has heard the horror stories. After months of meticulous planning, you arrive at the convention center, pry open your crate, and find a cracked monitor or a deep scratch across your main graphic panel. Panic sets in. Finding a last-minute fix on the show floor is a nightmare, forcing you to present a damaged, unprofessional front to thousands of potential customers.

This is precisely the moment you'll wish you had invested in purpose-built shipping cases for trade shows. They are much more than just boxes; they are a core component of your event strategy, often making the difference between a seamless setup and a frantic scramble. Protecting your gear ensures that every dollar spent on a beautiful display actually gets seen by your audience.

Protecting Your Most Valuable Assets

Your trade show exhibit is a significant investment. Every piece, from custom lighting and high-resolution screens to carefully printed graphics, is designed to tell your brand's story. These elements are not only expensive but also fragile. A purpose-built shipping case offers a level of protection that cardboard boxes or flimsy containers simply cannot match.

Here’s what you get when you invest in quality:

- Damage Prevention: Custom foam interiors and tough, rigid exteriors absorb the shocks and jolts of transit, keeping sensitive electronics and delicate finishes safe.

- Increased Efficiency: Quality cases feature durable wheels and ergonomic handles, making it faster and easier to move your exhibit from the loading dock to your booth space, which can reduce labor costs.

- Long-Term Savings: A solid set of cases will pay for itself after just a few shows by preventing expensive repairs and last-minute replacements.

A robust case isn’t just about protection; it's about predictability. It ensures that the stunning custom booth you approved in the design phase is the exact same one your audience will experience on opening day.

With in-person events back in full swing, logistics are more critical than ever. The average exhibitor at a major U.S. trade show uses between two and five shipping cases. During peak season, that means over 120,000 cases are in transit across the country.

You can get more insights on the industry's rebound at Wavecnct. Protecting the investment you've made in your exhibit starts with the right case, and you can explore what you'll be protecting with our durable and secure custom booths.

Choosing the Right Shipping Case for Your Exhibit

Selecting the right shipping cases for trade shows isn't just about finding a box that fits. It’s a strategic decision that balances protection, cost, and weight—all of which directly impact your setup time and event budget. Get it right, and your booth arrives looking flawless. Get it wrong, and you’re scrambling for last-minute repairs.

Think of it like choosing a vehicle. A heavy-duty, ATA-rated plywood case is your armored truck for transporting fragile, high-value gear like large monitors or custom light fixtures. Conversely, a lightweight molded plastic case is like a reliable SUV—perfect for sturdy items like pop-up banners and literature stands where managing weight to control drayage fees is a top priority.

Material and Construction: The Foundation of Protection

The core of a great shipping case is its material. Different materials serve different purposes, so matching the case to its contents and your show schedule is key to a smart investment.

Here's a breakdown of the most common options:

- ATA-Rated Plywood Cases: These are the heavyweights, engineered to survive a minimum of 100 shipments. With reinforced steel corners and recessed hardware, they are the top-tier choice for anything delicate, expensive, or custom-made.

- Molded Plastic Cases: Typically made from polyethylene, these cases offer a great balance between solid protection and manageable weight. They resist moisture and impacts, making them a fantastic all-around workhorse for most standard booth components.

- Fabric and Soft-Sided Bags: While not technically "cases," they serve a purpose for non-fragile items like pole hardware or rolled graphics. Their biggest advantage is being lightweight and easy to store, but they offer minimal protection against drops or impacts.

A great case is more than just a box; it's your exhibit's personal insurance policy. If you have a complex modular display with many different pieces, it's smarter to invest in several specialized cases designed for specific components rather than trying to cram everything into one giant crate.

Comparing Shipping Case Materials and Protection Levels

To simplify your decision, here’s how the most common materials stack up. Each has pros and cons depending on what you’re shipping and how often you exhibit.

| Case Material | Durability | Average Weight | Cost | Best For |

|---|---|---|---|---|

| ATA-Rated Plywood | Extremely High (100+ trips) | Heavy | High | Fragile electronics, custom displays, and high-value equipment. |

| Molded Plastic | High (50-100 trips) | Medium | Medium | Pop-up displays, banner stands, modular components, and lighting. |

| Rotomolded Plastic | Very High (75+ trips) | Medium-Heavy | High | Heavier standard equipment and items needing extra impact resistance. |

| Fabric/Soft Bags | Low | Very Light | Low | Rolled graphics, pole hardware, and non-fragile accessories. |

Your choice here directly influences both your upfront investment and your long-term shipping costs. A heavier, more durable case costs more initially and adds to drayage fees, but it can save you thousands in avoided repairs down the line.

Nailing Customization and Sizing

Once you've selected the right material, the interior is just as critical. A tough exterior shell is useless if your components are rattling around inside.

First, measure the largest single item going into the case. Then, add at least two inches of clearance on all sides for foam padding—this is non-negotiable. It’s the cushion that absorbs shocks and vibrations from the loading dock to the show floor.

You have two primary options for interior protection:

- Die-Cut Foam: This premium, custom-fit solution involves foam cut to the exact shape of your equipment, holding it perfectly snug. It's the best choice for sensitive electronics or one-of-a-kind display pieces.

- Pick-and-Pluck Foam: A more flexible option, this foam is pre-scored into small cubes that you can remove to create a custom-shaped cavity. It offers excellent protection and allows you to reconfigure the interior if you swap out your equipment.

Even with the rise of virtual events, exhibitors are getting smarter about shipping. A recent survey noted that 27% of exhibitors have cut their shipping footprint by at least one case per show. This isn't about shipping less—it's about shipping smarter with higher-quality, better-organized cases for the gear that truly matters.

If you want to dig deeper into the different types of containers, take a look at our complete guide to booth transport cases. Making the right call now will save you from major headaches and expenses later on.

Mastering How to Pack Your Trade Show Booth

Let’s be honest: packing is the part of the trade show process everyone dreads. But getting it right is more than just cramming things into a box. A smart, repeatable packing system is your secret weapon—it saves time, prevents costly damage, and drastically reduces stress on the show floor.

The goal is to create a system where setting up your booth is a smooth, predictable operation, not a frantic treasure hunt. The core of this system is a visual "packing map" for each of your shipping cases for trade shows. This isn't just a list; it's a strategic plan that dictates exactly where every component goes, ensuring a snug fit that prevents items from shifting and breaking in transit.

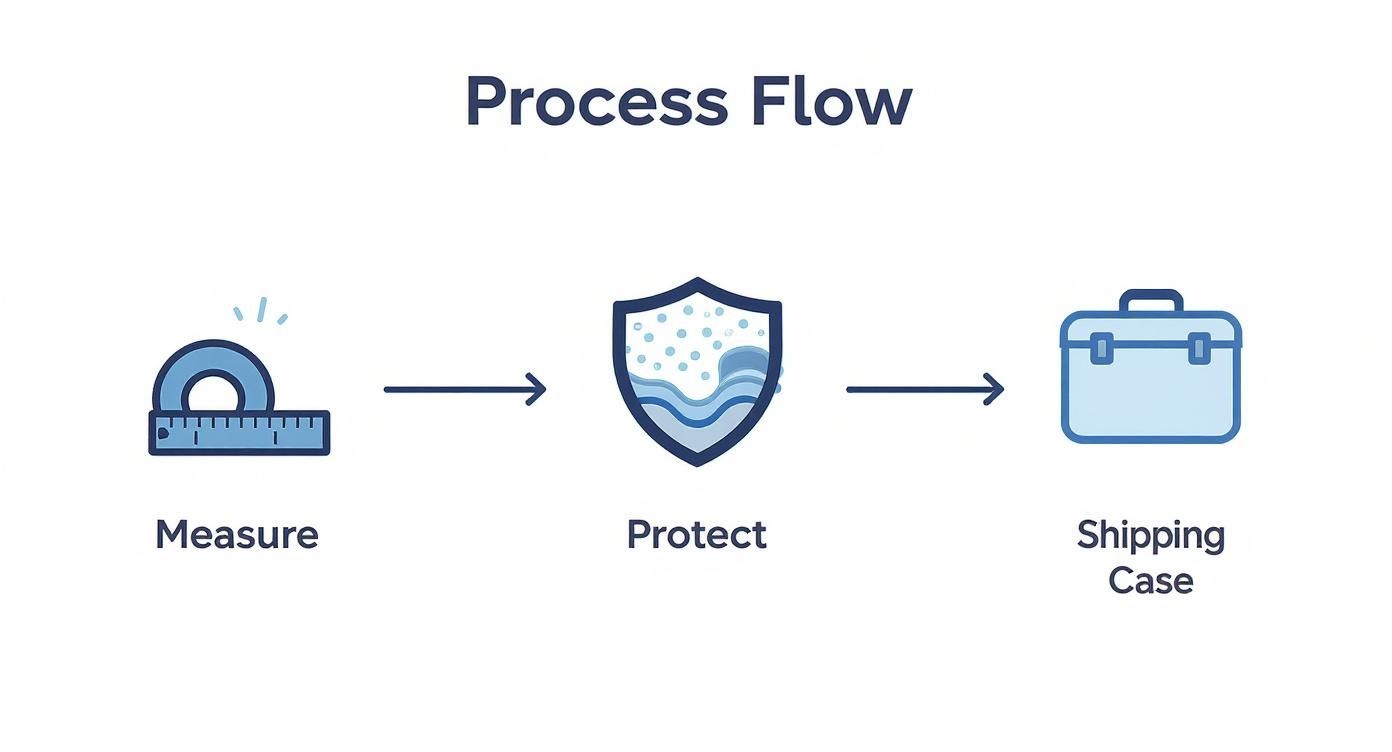

This simple guide lays out the essentials: measuring, protecting, and choosing the right case for all your gear.

When you follow a solid process, that high-quality shipping case you invested in can actually do its job and give your booth components the protection they need.

Developing Your Packing System

An effective packing system combines smart techniques with clear documentation. Think of each case as a self-contained kit where every item has a designated home.

Start by layering heavier, sturdier components at the bottom. Use foam inserts or padding to cushion them and fill any gaps. Lighter, more delicate pieces always go on top, separated by protective padding. This simple layering method prevents heavy items from crushing fragile ones.

For particularly valuable or fragile exhibit components, it's worth looking into specialized fine art packing and shipping techniques. The principles art movers use to protect priceless items are directly applicable to high-value displays.

Here are a few pro tips to make a huge difference:

- Tame Wiring Chaos: Use reusable cable ties to bundle all electrical cords, chargers, and extension cables. Place them in a clearly labeled accessory bag so they're easy to find during setup.

- Protect Your Graphics: Always roll printed graphics with the printed side facing inward. This simple habit prevents scratches and scuffs. For fabric graphics, proper care is even more important; learn more about how to store and care for your fabric trade show displays to make them last.

- Create a Master Inventory: This is non-negotiable. The document is your packing bible, listing the contents of every numbered case. It’s helpful during setup and a lifesaver during tear-down.

Your master inventory checklist is your single source of truth. When the show ends and your team is exhausted, this document prevents costly mistakes and ensures every component makes it back home safely.

Labeling for Absolute Clarity

Finally, implement a foolproof labeling system. Every case needs a clear, durable label that gives freight handlers and your setup crew all essential information at a glance. Don't just scribble "Booth Stuff" on the side with a marker.

Your labels should always include:

- Case Number: (e.g., "Case 1 of 4")

- Your Company Name & Booth Number:

- A Brief Content List: (e.g., "Backlit Panel & Power Cords")

- Orientation Arrows: Use large, clear "This Side Up" arrows to guide handlers.

This level of detail eliminates confusion on the loading dock and helps the setup crew work faster by allowing them to grab the cases they need in the right order. A clear system transforms packing from a painful chore into a competitive advantage.

Navigating Trade Show Shipping and Drayage Fees

Getting your exhibit to the venue is a victory, but it's only half the battle. Now you must navigate the world of trade show freight, where hidden costs and complex rules can quickly inflate your budget. Understanding these logistics is crucial for keeping expenses on track and ensuring your shipping cases for trade shows arrive at your booth without issue.

Your first major decision is choosing your shipping destination. You have two main choices, each with its own pros and cons.

Advance Warehouse vs. Direct to Show

Shipping to the advance warehouse is a popular strategy. This means your crates arrive at an off-site facility managed by the show’s general contractor, often up to 30 days before the event. This route typically offers a better material handling rate and, more importantly, provides a buffer against last-minute shipping delays. The contractor then moves your cases from the warehouse to your booth space before you arrive.

The alternative is shipping direct to show. Your carrier delivers everything straight to the convention center's loading dock, but you must adhere to a very specific and often narrow move-in window. While it might seem simpler, it leaves you vulnerable to shipping delays, and a late truck can be a disaster. Additionally, you’ll often pay higher handling fees due to the chaotic environment of the show floor.

For most exhibitors, the advance warehouse is the smarter, safer bet. It builds a much-needed buffer into your schedule and saves you the white-knuckle stress of a last-minute shipping crisis.

Understanding Drayage (Material Handling)

As soon as your shipment arrives, you'll encounter drayage, also known as material handling. This is the fee the show contractor charges for moving your freight from the dock to your booth, storing your empty cases during the event, and returning them for pack-up. It's unavoidable and often one of the largest line items on your final invoice.

Drayage is calculated by weight and billed in 100-pound increments known as CWT (hundredweight). The secret to controlling these fees is simple: ship fewer, lighter pieces.

- Consolidate Everything. Instead of shipping four separate cases, strap them securely onto a single pallet. A single 400-pound pallet will cost far less in drayage than four individual 100-pound cases because it’s one simple move for the on-site crew.

- Choose Lighter Cases. If your booth components don't require maximum protection, consider using lighter molded plastic cases instead of heavy ATA-rated ones. Trimming just 20-30 pounds from each case can lead to significant savings.

If managing these logistics feels overwhelming, consider partnering with specialized trade show mover services to take the burden off your shoulders. It's also helpful to see how these fees fit into the bigger picture; understanding the full trade show booth rental cost helps you budget more accurately for drayage and other services.

The logistics of shipping cases are tied directly to global freight trends. The top 10 U.S. ports handle 79% of all containerized freight. When global shipping rates spike, trade show managers feel the pain, seeing a 12–18% jump in costs that trickles down to every major event.

Ready to create a trade show presence that turns heads and drives results? The team at Storm Displays specializes in designing and building stunning exhibits that are as strategic as they are beautiful. Explore our custom booth solutions and request a quote today!